KING TONY production process and quality

King Tony is specialized in forging technology to create better metal configuration. Non-straight grain flow and non-sharp corners can extend lifetime and durability of socket. Torque is transmitted along the grain to make the socket more durable and thus increase safety during work.

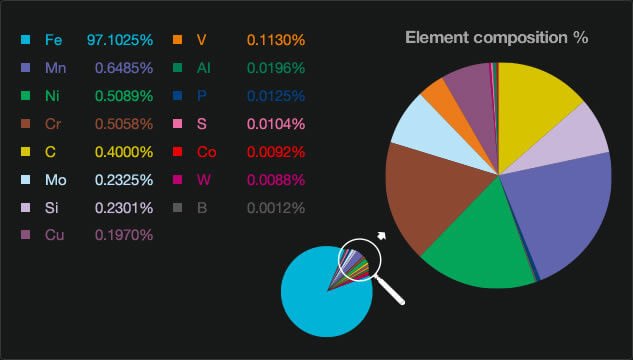

Tools are made to extend hand work. King Tony selects different material depending on the type of tool and the nature of its application - for tightening, power impacting, cutting, rotating, and locking. A high quality material of the right type must be used in order to meet the required lifetime for professional use.

King Tony controls heat treatment systems - heating and cooling processes - in order to ensure the right hardness without the brittleness is achieved. In the microstructural picture above you can see all elements are well- distributed.

Quality control is an important step in the production process which ensures a sufficient high level of quality of the production is achieved. King Tony uses advanced technology to inspect tiny difference on each step. Our hand socket, ratchet, extension bar, and power handle is 30% higher than international DIN standards. Impact socket reach 50% higher torque than DIN standards.